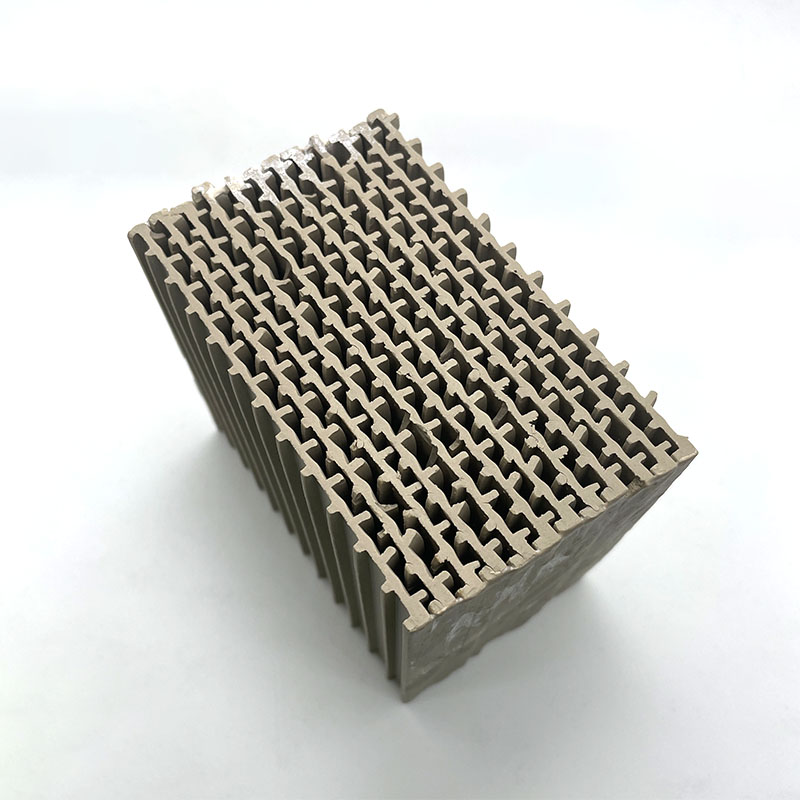

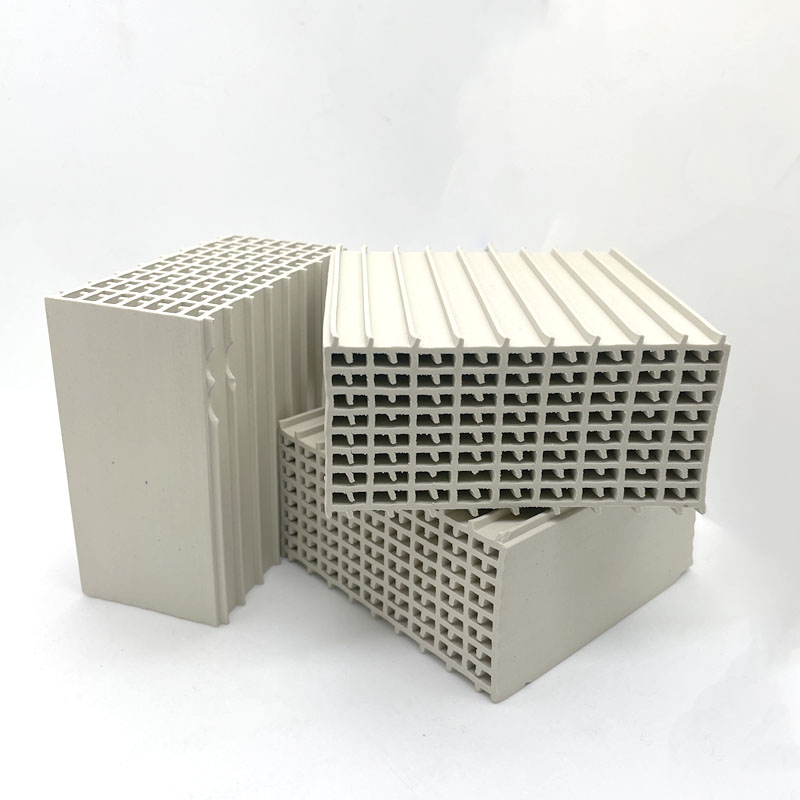

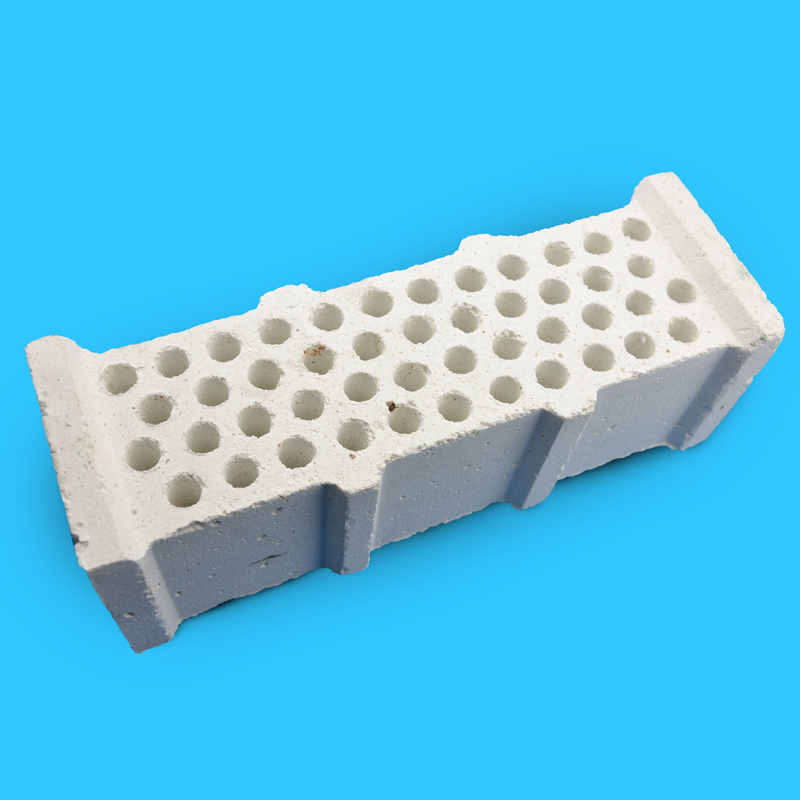

Honeycomb ceramic regenerator for regenerative thermal incinerator

Product model: 160 type, 180 type and 200 type

Product Specifications: 305mm×305mm×101mm; 101mm×101mm×101mm

Main technical indicators:

|

Item |

Unit |

MLM-160 |

MLM-180 |

MLM-200 |

|

Porosity |

% |

60 |

56 |

54 |

|

Maximum operating temperature |

ºC |

1180 |

1180 |

1180 |

|

Heat capacity |

kJ/kg.k |

0.79 |

0.88 |

0.92 |

|

Crushing strength |

kN/cm2 |

35 |

38 |

40 |

|

Water absorption |

% |

<0.5 |

<0.5 |

<0.5 |

|

Specific surface area |

m2/m3 |

524 |

590 |

660 |

|

Test weight |

kg/m3 |

900 |

998 |

1060 |

|

Bulk density |

g/cm3 |

2.25-2.35 |

2.25-2.35 |

2.25-2.35 |