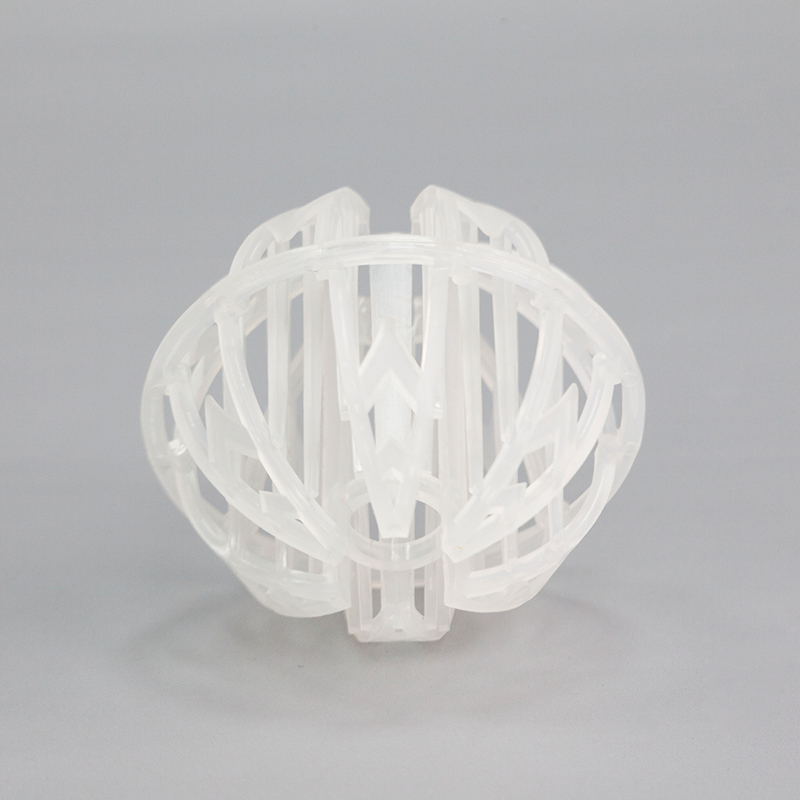

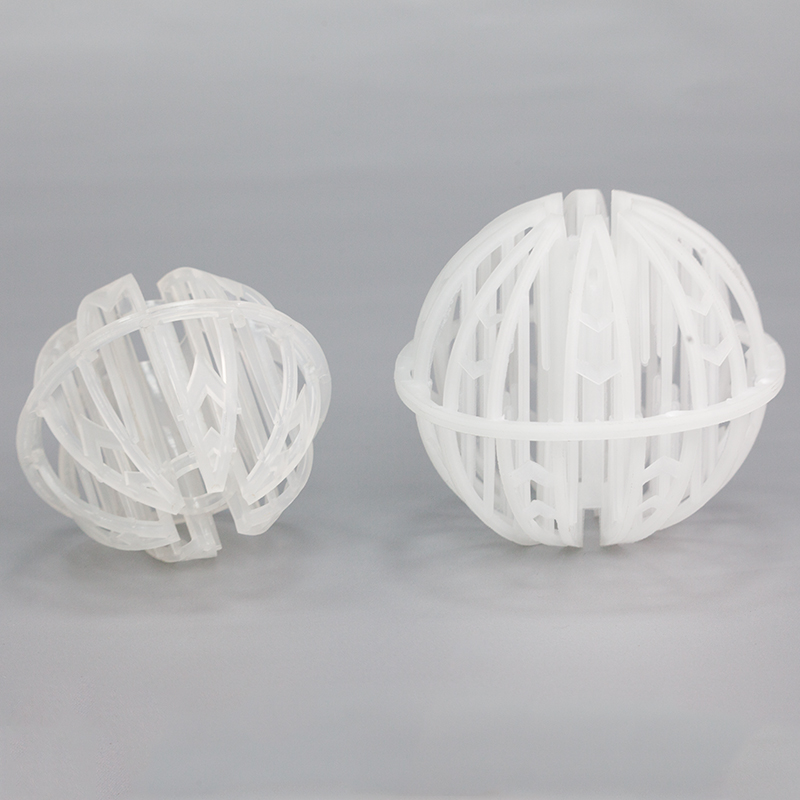

Plastic Tri-pak with PP/PE/ CPVC

Technical Data Sheet

|

Product Name |

Plastic Tri-Pak |

||||

|

Material |

PP, PE, PVC, CPVC, PPS , PVDF |

||||

|

Life Span |

>3 years |

||||

|

Size mm |

Surface Area m2/m3 |

Void Volume % |

Packing Number pieces/ m3 |

Packing Density Kg/m3 |

Dry Packing Factor m-1 |

|

25 |

85 |

90 |

81200 |

81 |

28 |

|

32 |

70 |

92 |

25000 |

70 |

25 |

|

50 |

48 |

93 |

11500 |

62 |

16 |

|

95 |

38 |

95 |

1800 |

45 |

12 |

|

Feature |

|

||||

|

Advantage |

|

||||

|

Application |

2. Liquid extraction 3. Gas & Liquid Seperation 4. Water treatment |

||||

Physical & Chemical properties

| Performace/Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

| Density(g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

| Operation Temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

| Chemical Corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

| Compression Strength(Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |