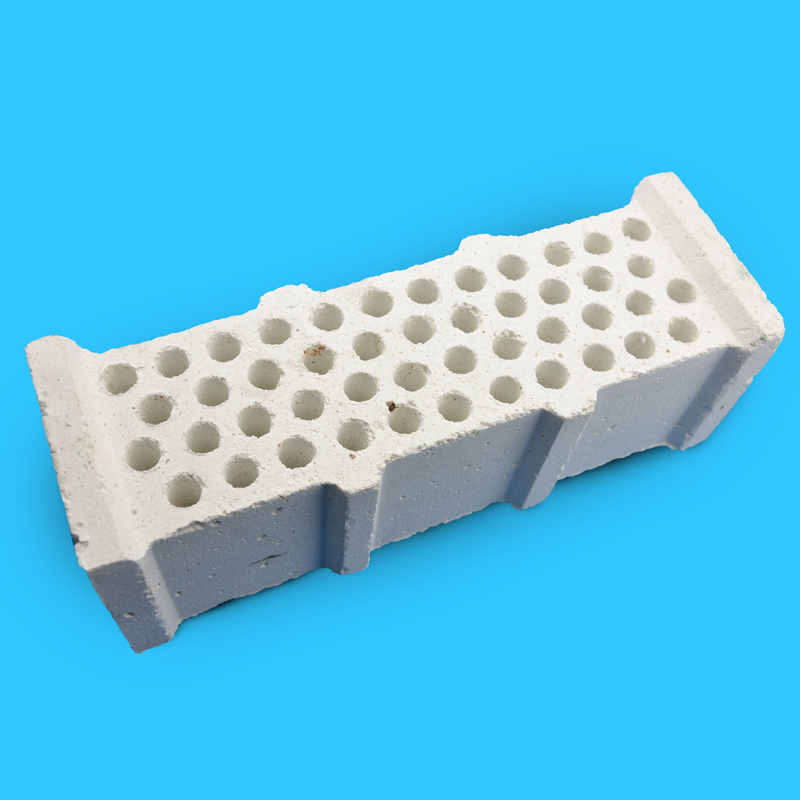

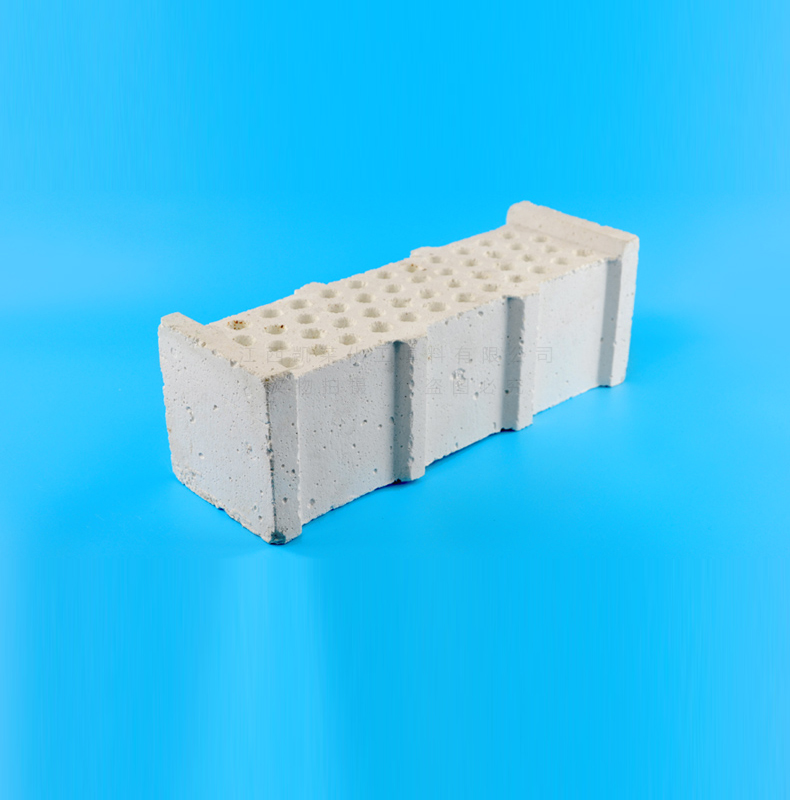

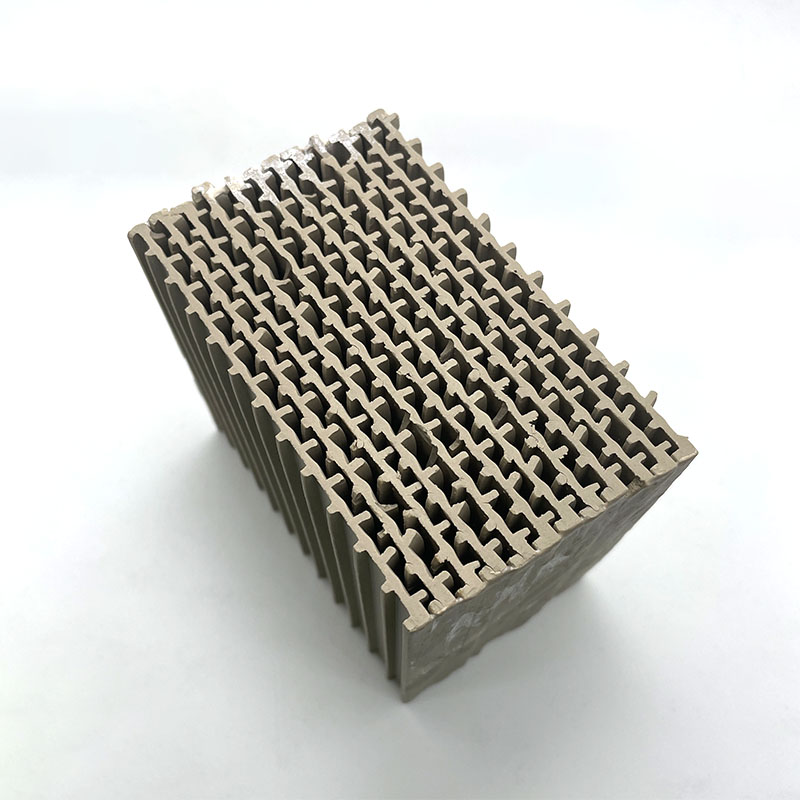

Honeycomb Protective Blocks for RTO

Functions

Its function is to protect the heat storage body and prolong the heat storage system. The service life of the heating body. Therefore, heat storage performance and thermal shock performance are the primary factors for selecting baffle bricks. The baffle brick produced by our company has the characteristics of good thermal shock stability, high softening point, strong resistance to chemical erosion, and good thermal shock resistance, which can ensure the performance and service life of the heat storage body during use. Reduce the downtime of steel mills and reduce production costs. The external dimensions and structure can be produced according to the requirements of the user's drawings. In addition to conventional materials such as mullite, corundum mullite, and fused corundum, baffle brick materials can also use chrome corundum mullite, which has excellent slag resistance and thermal erosion resistance, and can be used in harsh environments. Made of zirconium corundum mullite.

Application

Honeycomb protective blocks main applications: steel plants, waste incinerators, waste gas treatment thermal equipment, chemical plants, smelters, power plants, power industry boilers, gas turbines, engineering heating equipment, ethylene cracking furnaces, etc.

Technical Parameters

|

Item |

Corundum |

Mullite |

High Alumina Porcelain |

| Al2O3(%) |

80-86 |

56-65 |

53-60 |

| SiO3 (%) |

11-19 |

32-41 |

37-44 |

| Others (%) |

≤3.0 |

≤3.0 |

≤3.0 |

| Specific Gravity(g/m3) |

1.7 |

1.5 |

1.5 |

| Thermal Expansion

(X10-6/℃) |

6.5-8 |

7-8 |

7-8 |

| Max. Working Temp.(℃) |

1650 |

1450 |

1350 |

|

Size(mm) |

Channel Width(mm) |

Inner wall Thickness |

Specific surface area |

Free Cross Section |

|

200x80x100 |

14 |

6-8 |

87 |

36 |

|

250x80x100 |

14 |

6-8 |

87 |

36 |

|

300x80x100 |

14 |

6-8 |

87 |

36 |

|

350x80x100 |

14 |

6-8 |

87 |

36 |

|

400x80x100 |

14 |

6-8 |

87 |

36 |

|

450x80x100 |

14 |

6-8 |

87 |

36 |

|

500x80x100 |

14 |

6-8 |

87 |

36 |

|

200x100x100 |

14 |

6-8 |

80 |

34 |

|

250x100x100 |

14 |

6-8 |

80 |

34 |

|

300x100x100 |

14 |

6-8 |

80 |

34 |

|

350x100x100 |

14 |

6-8 |

80 |

34 |

|

400x100x100 |

14 |

6-8 |

80 |

34 |

|

450x100x100 |

14 |

6-8 |

80 |

34 |

|

500x100x100 |

14 |

6-8 |

80 |

34 |

|

600x100x100 |

14 |

6-8 |

80 |

34 |