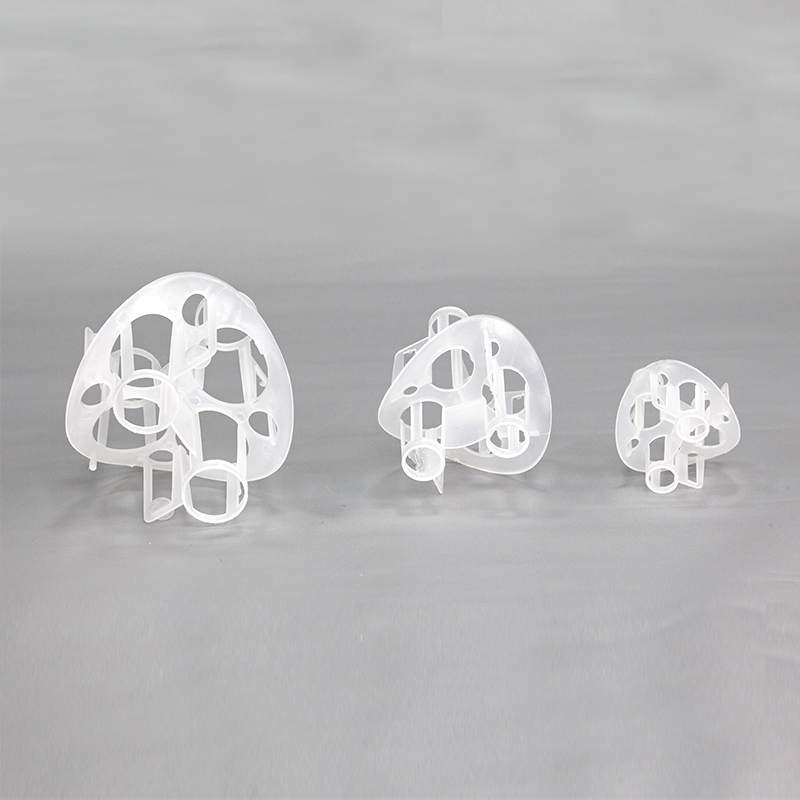

Plastic Heilex Ring With PP / PE/CPVC

Plastic Heilex Ring :The saddle shape is the main body, the cone is open to the cylinder, which increases the specific surface area and porosity, and improves the distribution of gas and liquid in the packing layer. Low pressure drop, uniform gas-liquid distribution in the packing layer, and strong anti-fouling performance. Suitable for gas absorption and acid gas desorption, washing and fertilizer production, etc.

Material

Our Factory assure all tower packing made from 100% Virgin Material.

Technical Data Sheet

|

Product Name |

Plastic Heilex Ring |

||||

|

Material |

PP,RPP,PE,PVC,CPVC,PVDF,etc. |

||||

|

Life Span |

>3 years |

||||

|

Size mm |

Surface Area m2/m3 |

Void Volume % |

Packing Number pieces/ m3 |

Packing Density Kg/m3 |

Dry Packing Factor m-1 |

|

50 |

107 |

94 |

8000 |

50 |

128 |

|

76 |

75 |

95 |

3420 |

45 |

87 |

|

100 |

55 |

96 |

1850 |

48 |

62 |

|

Feature |

High void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high efficiency of mass transfer. | ||||

|

Advantage |

1. Their special structure make it has big flux, low pressure drop, good anti-impaction capability.

2. Strong resistance to chemical corrosion, large void space. energy saving, low operation cost and easy to be load and unload. |

||||

|

Application |

Gas absorption, Acidic gases deabsorption system, Washing, Fertilizer production.

These various plastic tower packing are widely used in petroleum and chemical,alkali chloride,gas and environmental protection industries with max. temperature of 280°. |

||||

Physical & Chemical properties

| Performace/Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

| Density (g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

| Operation Temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

| Chemical Corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

| Compression Strength (Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |