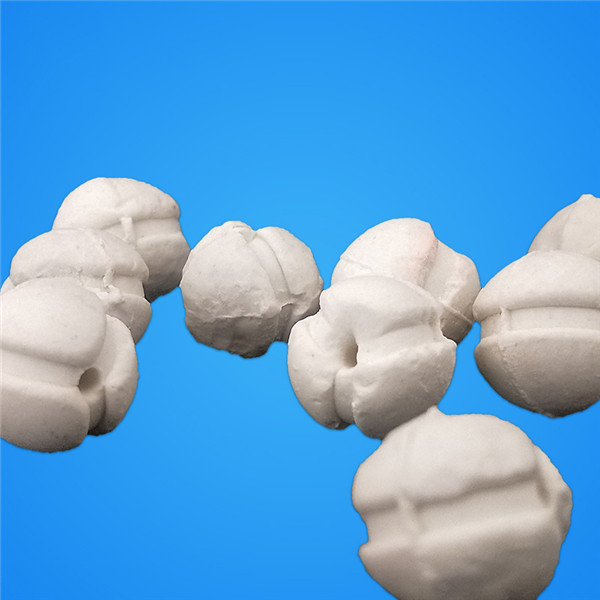

Porous Ceramic Ball Manufacturer with different size

Application

Porous ceramic ball is a new product developed on the basis of the inert alumina ceramic ball. It takes the diameter of the ball as the axis to open the hole. It not only has certain mechanical strength, chemical stability and thermal stability, but also increases the specific surface area. And the void ratio, thereby increasing the dispersion and flux of the material, and reducing the resistance of the system. It can be widely used in petroleum, chemical and natural gas industries to replace inert alumina ceramic balls as catalyst covering support fillers.

Physical Properties

|

Type |

Feldspar | Feldspar- Molai | Molai Stone | Molai- Corundum | Corundum | |||||

|

Item |

||||||||||

|

Chemical Content |

Al2O3 |

20-30 |

30-45 |

45-70 |

70-90 |

≥90 |

||||

|

Al2O3+ SiO2 |

≥90 |

|||||||||

|

Fe2O3 |

≤1 |

|||||||||

| Water Adsorption (%) |

≤5 |

|||||||||

| Acid Resistance (%) |

≥98 |

|||||||||

| Alkaki Resistance (%) |

≥80 |

≥82 |

≥85 |

≥90 |

≥95 |

|||||

| Operation Temperature(°C) |

≥1300 |

≥1400 |

≥1500 |

≥1600 |

≥1700 |

|||||

|

Crushing Strength (N/Piece) |

Φ3mm |

≥400 |

≥420 |

≥440 |

≥480 |

≥500 |

||||

|

Φ6mm |

≥480 |

≥520 |

≥600 |

≥620 |

≥650 |

|||||

|

Φ8mm |

≥600 |

≥700 |

≥800 |

≥900 |

≥1000 |

|||||

|

Φ10mm |

≥1000 |

≥1100 |

≥1300 |

≥1500 |

≥1800 |

|||||

|

Φ13mm |

≥1500 |

≥1600 |

≥1800 |

≥2300 |

≥2600 |

|||||

|

Φ16mm |

≥1800 |

≥2000 |

≥2300 |

≥2800 |

≥3200 |

|||||

|

Φ20mm |

≥2500 |

≥2800 |

≥3200 |

≥3600 |

≥4000 |

|||||

|

Φ25mm |

≥3000 |

≥3200 |

≥3500 |

≥4000 |

≥4500 |

|||||

|

Φ30mm |

≥4000 |

≥4500 |

≥5000 |

≥5500 |

≥6000 |

|||||

|

Φ38mm |

≥6000 |

≥6500 |

≥7000 |

≥8500 |

≥10000 |

|||||

|

Φ50mm |

≥8000 |

≥8500 |

≥9000 |

≥10000 |

≥12000 |

|||||

|

Φ75mm |

≥10000 |

≥11000 |

≥12000 |

≥14000 |

≥15000 |

|||||

| Bulk Density (kg/m3) |

1100-1200 |

1200-1300 |

1300-1400 |

1400-1550 |

≥1550 |

|||||

Size and Tolerance(mm)

|

Diameter |

6 /8 /10 |

13 /16 /20 /25 |

30 /38 /50 |

60 /75 |

|

Tolerance of diameter |

±1.0 |

±1.5 |

±2.0 |

±3.0 |

|

Pore diameter |

2-3 |

3-5 |

5-8 |

8-10 |