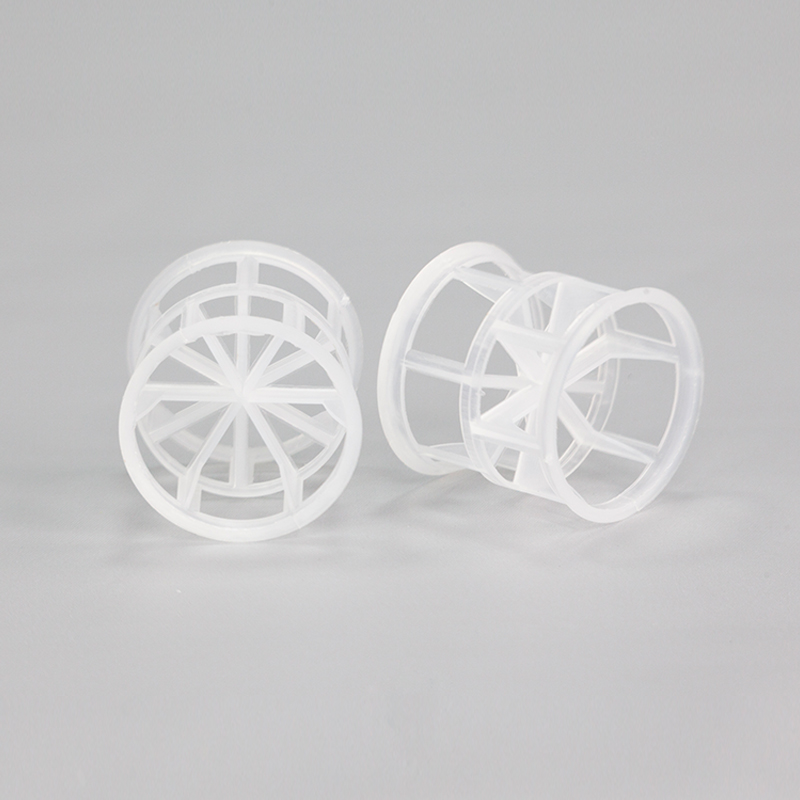

Plastic Ralu Ring With PP / PE/CPVC

Technical Data Sheet

|

Product Name |

Plastic Ralu Ring |

||||

|

Material |

PP,PE,RPP,PVC,CPVC,PVDF ,etc | ||||

|

Life Span |

>3 years |

||||

|

Size Inch/mm |

Surface Area m2/m3 |

Void Volume % |

Packing Number pieces/ m3 |

Packing Density Kg/m3 |

|

|

3/5” |

15 |

320 |

94 |

170000 |

80 |

|

1” |

25 |

190 |

88 |

36000 |

46.8 |

|

1-1/2” |

38 |

150 |

95 |

13500 |

65 |

|

2” |

50 |

110 |

95 |

6300 |

53.5 |

|

3-1/2” |

90 |

75 |

90 |

1000 |

40 |

|

5” |

125 |

60 |

97 |

800 |

30 |

|

Feature |

High void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high efficiency of mass transfer. | ||||

|

Advantage |

1. Their special structure make it has big flux, low pressure drop, good anti-impaction capability.

2. Strong resistance to chemical corrosion, large void space. energy saving, low operation cost and easy to be load and unload. |

||||

|

Application |

It is widely apply in all kinds of separation, absorption and desorption device, atmospheric and vacuum distillation device, decarburization and desulfurization system, ethylbenzene, iso-octane and toluene separation. | ||||

Physical & Chemical properties

| Performace/Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

| Density(g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

| Operation Temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

| Chemical Corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

| Compression Strength(Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |