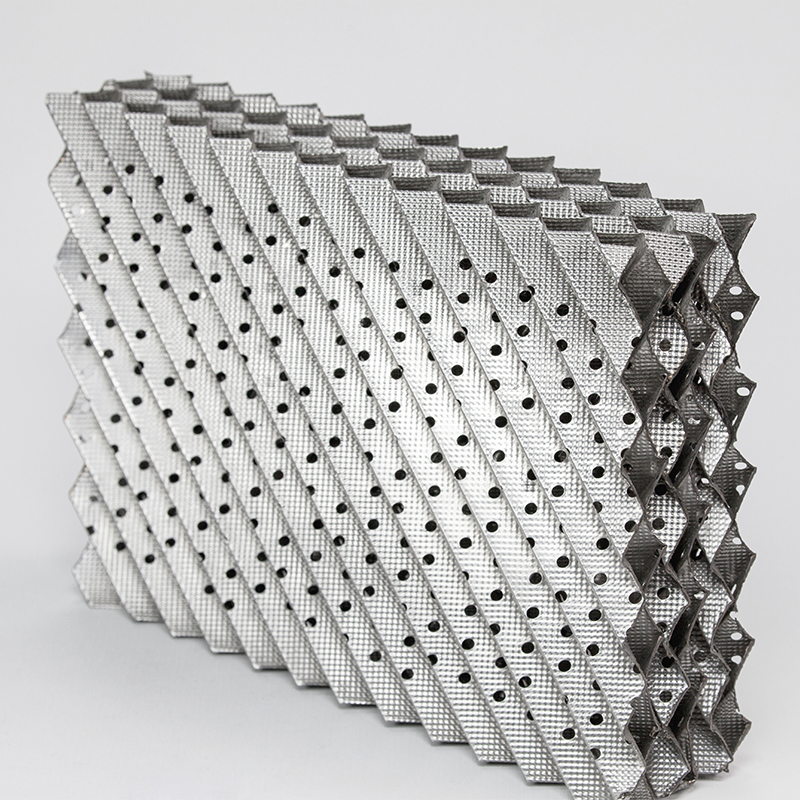

Metal Corrugated Plate Packing with SS304 / SS316

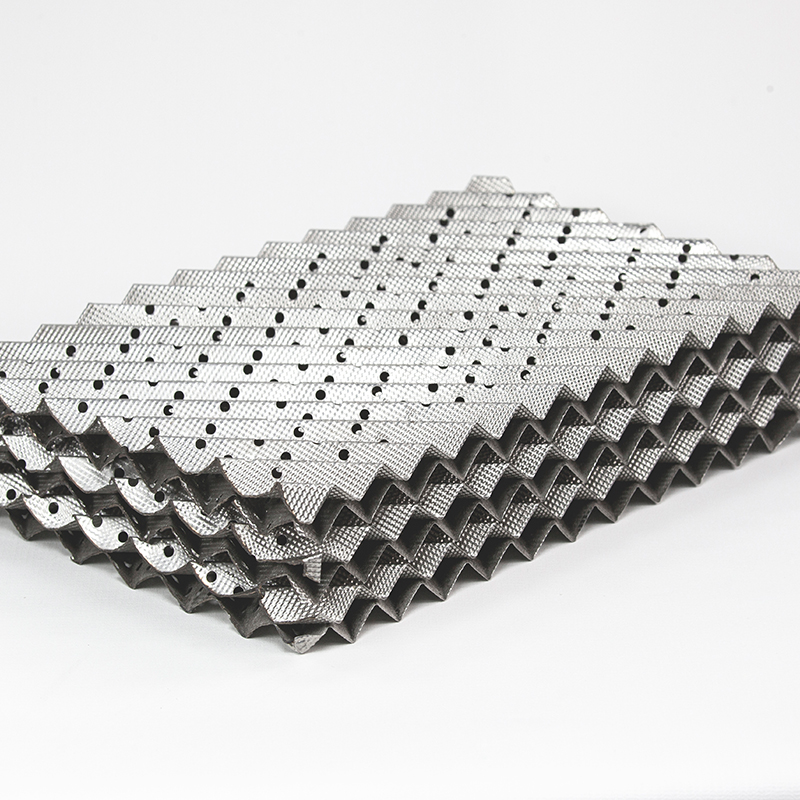

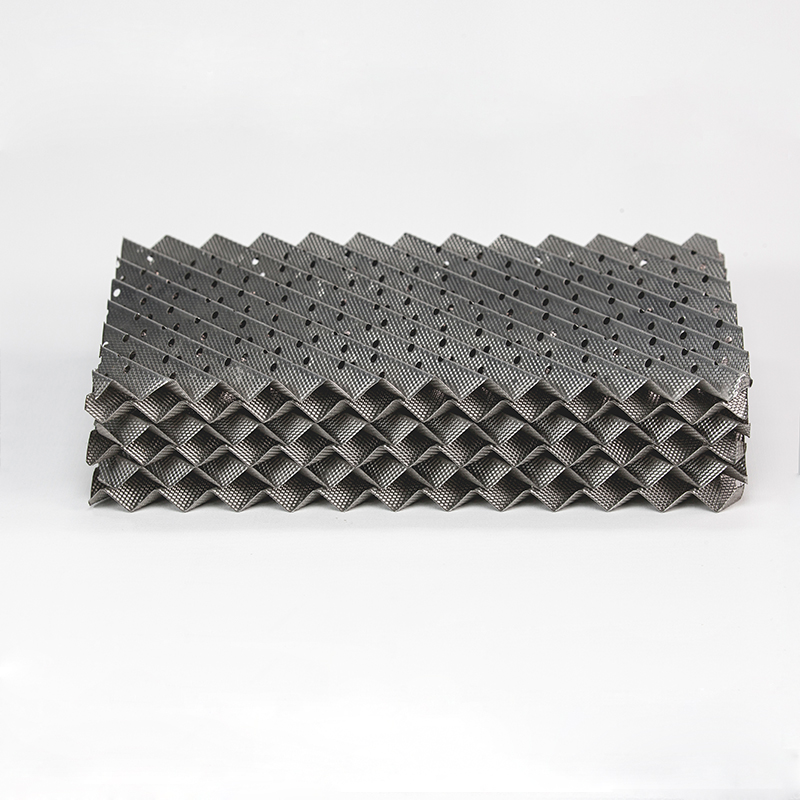

The diameter of the tower for processing packing ranges from φ150mm to 12000mm or more. Metal orifice corrugated packing is a kind of packing arranged in a uniform geometric pattern in the tower and neatly stacked. It stipulates the gas-liquid flow path, improves the channel flow and wall flow phenomenon, the pressure drop can be small, but at the same time it provides more specific surface area, and can achieve higher mass and heat transfer effects in the same volume. The structure is uniform, regular, and symmetric. When the metal orifice plate corrugated packing has the same specific surface area as the bulk packing, the porosity of the metal orifice plate corrugated packing is larger, and it has a larger flux. The comprehensive processing capacity is larger than that of the plate tower and the bulk packing tower. Therefore, various general structured packings represented by metal orifice plate corrugations are used in industry.

The effect of using metal orifice plate corrugated packing to transform the plate tower is particularly obvious. Through careful design, manufacturing, installation and careful operation, the industrial amplification effect can be made insignificant. Because structured packing has the advantages of reduced pressure, large flux, and high separation efficiency, it has been widely used in many towers in the fields of fine chemical industry, perfume industry, oil refining, fertilizer, petrochemical industry and so on.

Application

It is widely apply in the process of absorption and resolution. also in waste gas treatment and heat-exchange.

Perforated plate corrugated packing with the wide range of applications.

Diameter: 0.1-12m; Pressure: Vacuum to high pressure;

Liquid load: 0.2 to more than 300 m3 / m2.h;

System

Ethyl benzene/ styrene, Fatty acid, cyclohex anone/ cyclohexanol, caprolaction, etc, Absorption desorption.

Technical Date

|

Type |

Specific area m2/m3 |

Void % |

Hydraulic diameter mm |

F Factor |

Theoretical plate No/m |

Pressure drop Mm Hg/m |

|

125Y |

125 |

98.5 |

18 |

3 |

1-1.2 |

1.5 |

|

250Y |

250 |

97 |

15.8 |

2.6 |

2-3 |

1.5-2 |

|

350Y |

350 |

95 |

12 |

2 |

3.5-4 |

1.5 |

|

450Y |

450 |

93 |

9 |

1.5 |

3-4 |

1.8 |

|

500Y |

500 |

92 |

8 |

1.4 |

3-4 |

1.9 |