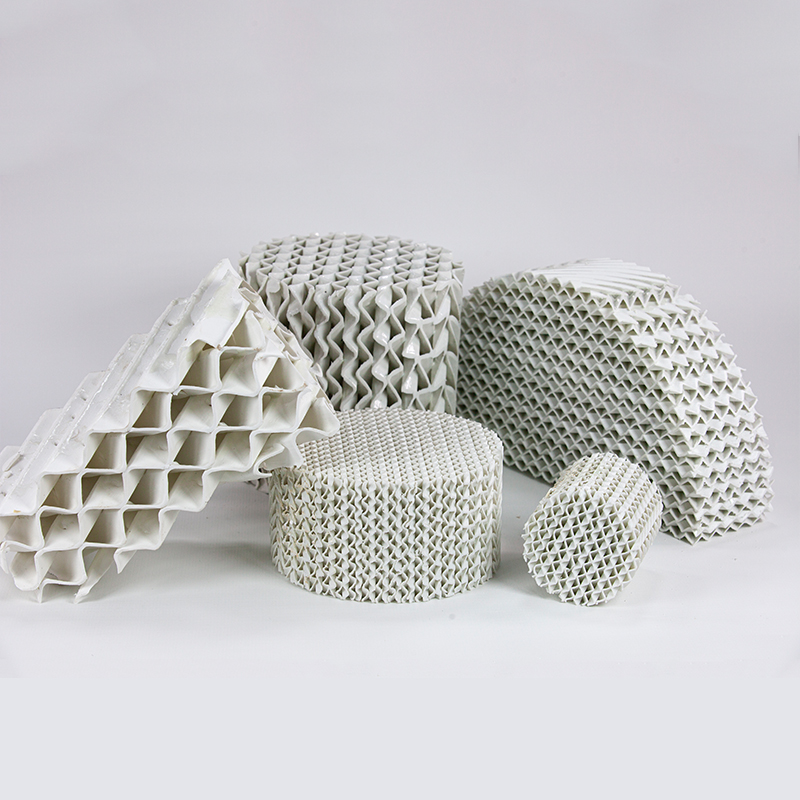

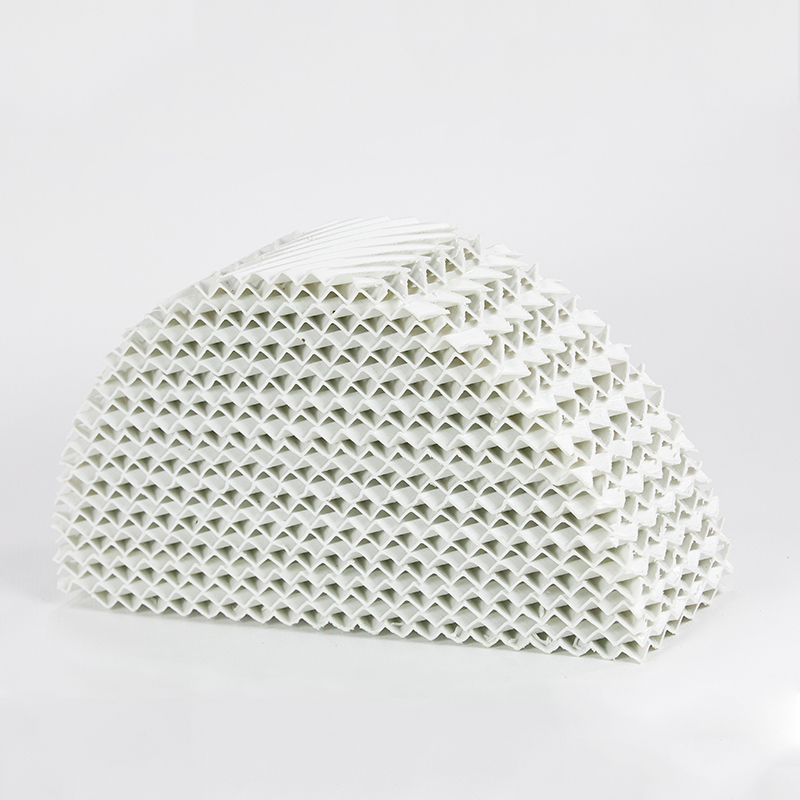

Manufacturer for Pp Structured Packing - Ceramic Structured Packing with type 125Y & 250Y – Kelley

Manufacturer for Pp Structured Packing - Ceramic Structured Packing with type 125Y & 250Y – Kelley Detail:

Because of ceramic unique structure, good hydrophilic performance, its surface can form a very thin liquid film of turbulent airflow tilt and tortuous channels can promote the air but not stop match the metal filler air can make the ceramic packing, and its corrosion resistance, high temperature resistant performance of metal filler can’t compared.Surface structure has good wetting property, can accelerate liquid flow, make the packing delay fluid volume to a minimum.To reduce the chance of overheating, aggregation, and coking.This product is made of high quality chemical porcelain clay raw material processing and become, resistant to high temperature and high pressure, good chemical stability and high strength, is an ideal carrier to support various types of catalysts.

Chemical Analysis

|

Composition |

Value |

|

SiO2 |

≥72% |

|

Fe2O3 |

≤0.5% |

|

CaO |

≤1.0% |

|

Al2O3 |

≥23% |

|

MgO |

≤1.0% |

|

Other |

2% |

Physical Property

|

Index |

Value |

|

Specific gravity(g/cm3) |

2.5 |

|

Water absorption (wt%) |

≤0.5 |

|

Acid resistance (wt%) |

≥99.5 |

|

Loss in burn (wt%) |

≤5.0 |

|

Max. Operating Temp.(℃) |

800 |

|

Crush strength (Mpa) |

≥130 |

|

Moh’s Hardness(Scale) |

≥7 |

Technical Date

|

Spec. |

Specific surface (m2/m3) |

Bulk density (kg/ m3) |

Void ratio (%) |

Obl. Angle |

Pressure drop (mm Hg/m) |

Theo. Plate (m-1) |

Hydraulic diameter (mm) |

Liquid load (m3/m2h) |

Max. Factor m/s (Kg/m3)-1 |

|

125Y |

125 |

320 |

90 |

45 |

1.8 |

1.8 |

28 |

0.2-100 |

3.0 |

|

250Y |

250 |

420 |

80 |

45 |

2 |

2.5 |

12 |

0.2-100 |

2.6 |

|

350Y |

350 |

470 |

78 |

45 |

2.5 |

2.8 |

10 |

0.2-100 |

2.5 |

|

450Y |

450 |

520 |

72 |

45 |

4 |

4 |

7 |

0.2-100 |

1.8 |

|

550Y |

550 |

620 |

74 |

45 |

5.5 |

5-6 |

6 |

0.18-100 |

1.4 |

|

700Y |

700 |

650 |

72 |

45 |

6 |

7 |

5 |

0.15-100 |

1.3 |

Product detail pictures:

Related Product Guide:

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for Manufacturer for Pp Structured Packing - Ceramic Structured Packing with type 125Y & 250Y – Kelley, The product will supply to all over the world, such as: Netherlands, Comoros, Southampton, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.