Manufacturer for Ceramic Random Packing - Ceramic Raschig Ring with 1/4″&1/2″& 5/8”&3/4”&1” – Kelley

Manufacturer for Ceramic Random Packing - Ceramic Raschig Ring with 1/4″&1/2″& 5/8”&3/4”&1” – Kelley Detail:

Application

45%AL2O3 Inert Alumina Ceramic Ball widely used in petroleum, chemical, fertilizer, gas and environmental protection industries, as a catalyst in the reactor to cover support material and tower packing.It has a high temperature and high pressure resistance, bibulous rate is low, the characteristics of the chemical performance is stable.Can withstand the erosion of acid, alkali and other organic solvents, and can endure in the production process of temperature changes.Its main function is to increase gas or liquid distribution points, support and protection intensity is not high of the catalyst.

Chemical Composition

|

Al2O3+SiO2 |

Al2O3 |

SiO2 |

Fe2O3 |

MgO |

K2O+Na2O+CaO |

Other |

|

> 92% |

45% |

47% |

<1% |

<2.5% |

<4% |

<0.5% |

Leach able Fe2O3is less than 0.1%

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<0.5 |

|

Bulk density (g/cm3) |

1.38-1.5 |

|

Specific gravity (g/cm3) |

2.3-2.4 |

|

Free volume (%) |

40 |

|

Operation temp.(max) (℃) |

1250 |

|

Moh’s hardness (scale) |

>6.5 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

Crush Strength

|

Size |

Crush strength |

|

|

Kgf/particle |

KN/particle |

|

|

1/8”(3mm) |

>25 |

>0.25 |

|

1/4”(6mm) |

>60 |

>0.60 |

|

3/8”(10mm) |

>100 |

>1.00 |

|

1/2”(13mm) |

>230 |

>2.30 |

|

3/4”(19mm) |

>500 |

>5.0 |

|

1”(25mm) |

>700 |

>7.00 |

|

1-1/2”(38mm) |

>1000 |

>10.00 |

|

2”(50mm) |

>1300 |

>13.00 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

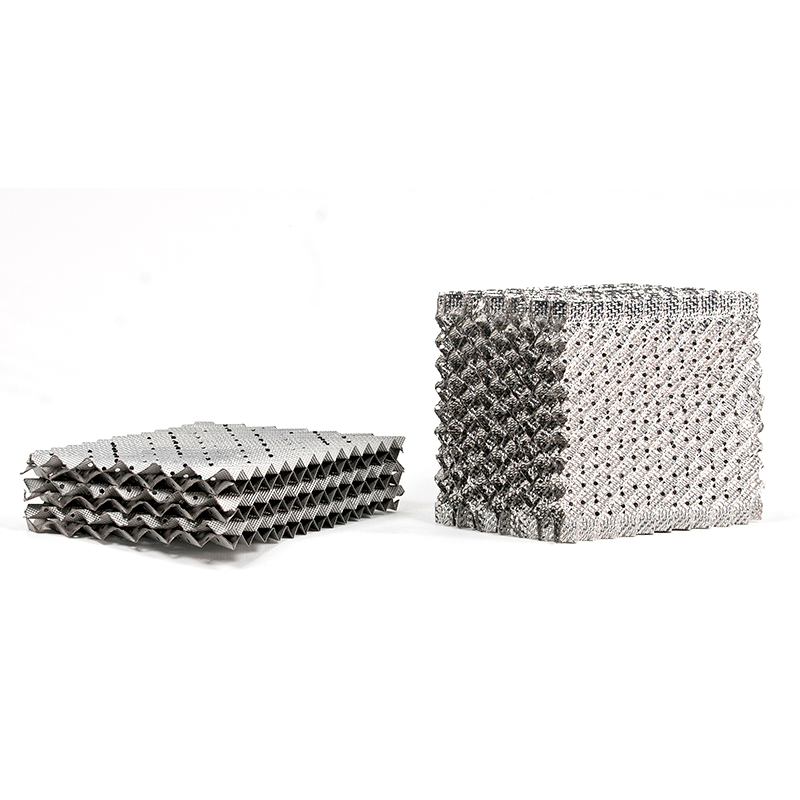

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Manufacturer for Ceramic Random Packing - Ceramic Raschig Ring with 1/4″&1/2″& 5/8”&3/4”&1” – Kelley, The product will supply to all over the world, such as: Seattle, Roman, Swiss, We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.