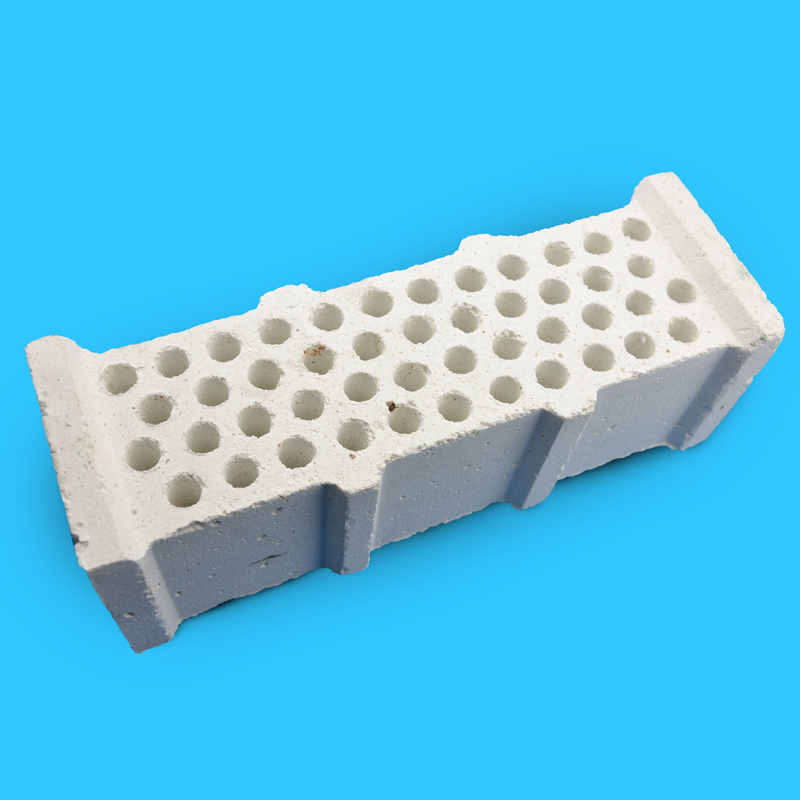

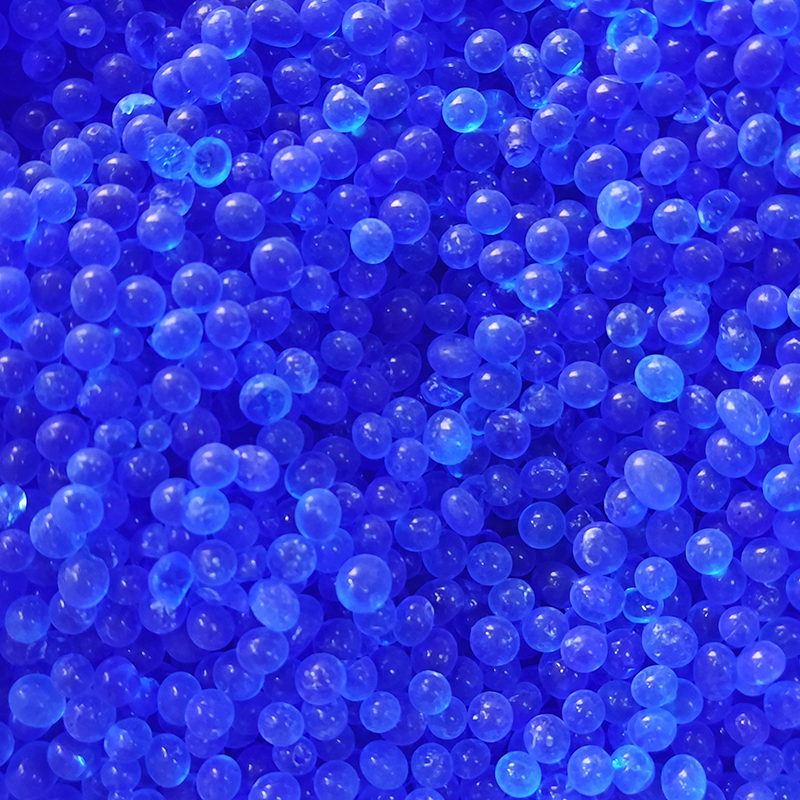

Good Quality Igel Ball Packing - 30% Inert Ceramic Ball – Catalyst Support Media – Kelley

Good Quality Igel Ball Packing - 30% Inert Ceramic Ball – Catalyst Support Media – Kelley Detail:

Application

30%AL2O3 type Inert Ceramic Ball are widely used in petroleum, chemical, fertilizer, gas and environmental protection industries, as a catalyst in the reactor to cover support material and tower packing.It has a high temperature and high pressure resistance, bibulous rate is low, the characteristics of the chemical performance is stable.Can withstand the erosion of acid, alkali and other organic solvents, and can endure in the production process of temperature changes.Its main function is to increase gas or liquid distribution points, support and protection intensity is not high of the catalyst.

Chemical Composition

|

Al2O3+SiO2 |

Al2O3 |

SiO2 |

Fe2O3 |

MgO |

K2O+Na2O+CaO |

Other |

|

> 92% |

30% |

62% |

<1% |

<2.5% |

<4% |

<0.5% |

Leach able Fe2O3is less than 0.1%

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<0.5 |

|

Bulk density (g/cm3) |

1.38-1.4 |

|

Specific gravity (g/cm3) |

2.3-2.4 |

|

Free volume (%) |

40 |

|

Operation temp.(max) (℃) |

1100 |

|

Moh’s hardness (scale) |

>6.5 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

Crush Strength

|

Size |

Crush strength |

|

|

Kgf/particle |

KN/particle |

|

|

1/8”(3mm) |

>20 |

>0.20 |

|

1/4”(6mm) |

>50 |

>0.50 |

|

3/8”(10mm) |

>85 |

>0.85 |

|

1/2”(13mm) |

>180 |

>1.80 |

|

3/4”(19mm) |

>430 |

>4.30 |

|

1”(25mm) |

>620 |

>6.20 |

|

1-1/2”(38mm) |

>880 |

>8.80 |

|

2”(50mm) |

>1200 |

>12.0 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

Product detail pictures:

Related Product Guide:

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for Good Quality Igel Ball Packing - 30% Inert Ceramic Ball – Catalyst Support Media – Kelley, The product will supply to all over the world, such as: Canada, Mongolia, US, With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.