Fast delivery Ceramic Ball Catalyst Support - 92% Inert Alumina Ball – Catalyst Support Media – Kelley

Fast delivery Ceramic Ball Catalyst Support - 92% Inert Alumina Ball – Catalyst Support Media – Kelley Detail:

Application

92% AL2O3 inert alumina ball is widely used in petroleum, chemical, fertilizer, gas, environmental protection and other industries. It is used as a catalyst covering carrier material and tower packing in the reactor. It has high temperature resistance, high pressure, low water absorption, stable chemical performance, and Withstand the erosion of organic solvents such as acids and alkalis, and can withstand temperature changes during the production process. Its main function is to increase the distribution point of gas or liquid, support and protect the catalyst with low strength.

Chemical Composition

|

Al2O3+SiO2 |

Al2O3 |

Fe2O3 |

MgO |

K2O+Na2O+CaO |

Other |

|

> 94% |

92% |

<1% |

0.1% |

<1% |

<0.5% |

Leach able Fe2O3 is less than 0.1%

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<4 |

|

Bulk density (g/cm3) |

1.8-2.0 |

|

Specific gravity (g/cm3) |

3.6 |

|

Free volume (%) |

40 |

|

Operation temp.(max) (℃) |

1550 |

|

Moh’s hardness (scale) |

>9 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

Crush Strength

|

Size |

Crush strength |

|

|

Kgf/particle |

KN/particle |

|

|

1/8”(3mm) |

>40 |

>0.4 |

|

1/4”(6mm) |

>80 |

>0.8 |

|

3/8”(10mm) |

>190 |

>1.90 |

|

1/2”(13mm) |

>580 |

>5.8 |

|

3/4”(19mm) |

>900 |

>9.0 |

|

1”(25mm) |

>1200 |

>12.0 |

|

1-1/2”(38mm) |

>1800 |

>18.0 |

|

2”(50mm) |

>2150 |

>21.5 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

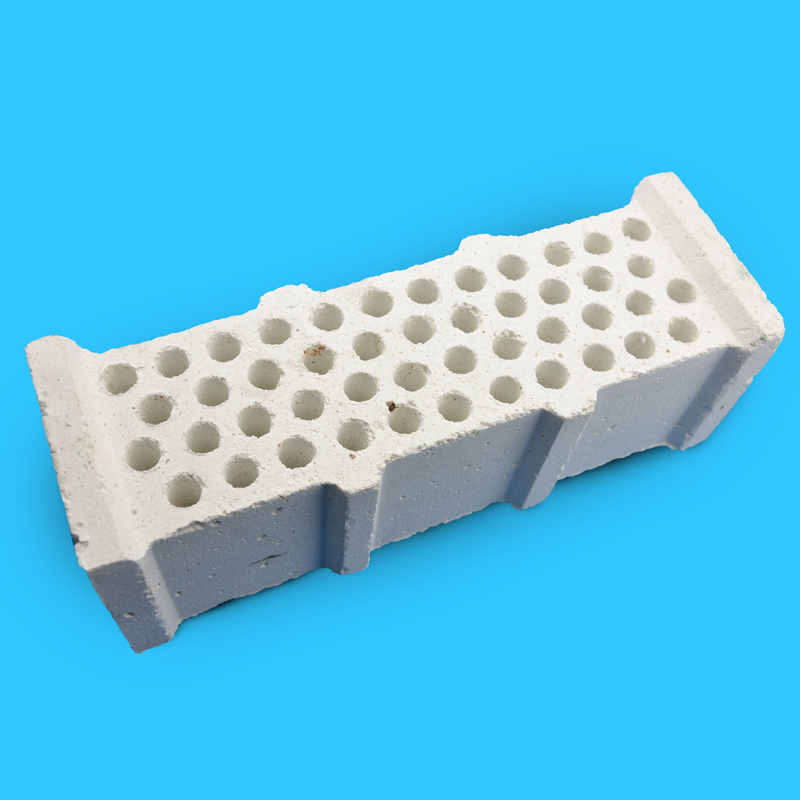

Product detail pictures:

Related Product Guide:

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for Fast delivery Ceramic Ball Catalyst Support - 92% Inert Alumina Ball – Catalyst Support Media – Kelley, The product will supply to all over the world, such as: belarus, Bangkok, Chile, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.