Factory made hot-sale Hollow Floating Ball Vendor - 17% Inert Ceramic Ball – Catalyst Support Media – Kelley

Factory made hot-sale Hollow Floating Ball Vendor - 17% Inert Ceramic Ball – Catalyst Support Media – Kelley Detail:

Application

17%AL2O3 Inert Alumina Ceramic Ball widely used in petroleum, chemical, fertilizer, gas and environmental protection industries, as a catalyst in the reactor to cover support material and tower packing.It has a high temperature and high pressure resistance, bibulous rate is low, the characteristics of the chemical performance is stable.Can withstand the erosion of acid, alkali and other organic solvents, and can endure in the production process of temperature changes.Its main function is to increase gas or liquid distribution points, support and protection intensity is not high activity of the catalyst.

Chemical Composition

|

Al2O3+SiO2 |

Al2O3 |

SiO2 |

Fe2O3 |

MgO |

K2O+Na2O+CaO |

Other |

|

> 93% |

> 17% |

60-70% |

<1% |

<0.5% |

<4% |

<1% |

Leach able Fe2O3is less than 0.1%

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<0.5 |

|

Bulk density (KGS/M3) |

1300-1450 |

|

Specific gravity (g/cm3) |

2.3-2.4 |

|

Free volume (%) |

40 |

|

Operation temp.(max) (℃) |

1200 |

|

Moh’s hardness (scale) |

>6.5 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

Crush Strength

|

Size |

Crush strength |

|

|

Kgf/particle |

KN/particle |

|

|

1/8”(3mm) |

>20 |

>0.20 |

|

1/4”(6mm) |

>50 |

>0.50 |

|

3/8”(10mm) |

>85 |

>0.85 |

|

1/2”(13mm) |

>180 |

>1.80 |

|

3/4”(19mm) |

>430 |

>4.30 |

|

1”(25mm) |

>620 |

>6.20 |

|

1-1/2”(38mm) |

>880 |

>8.80 |

|

2”(50mm) |

>1200 |

>12.0 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

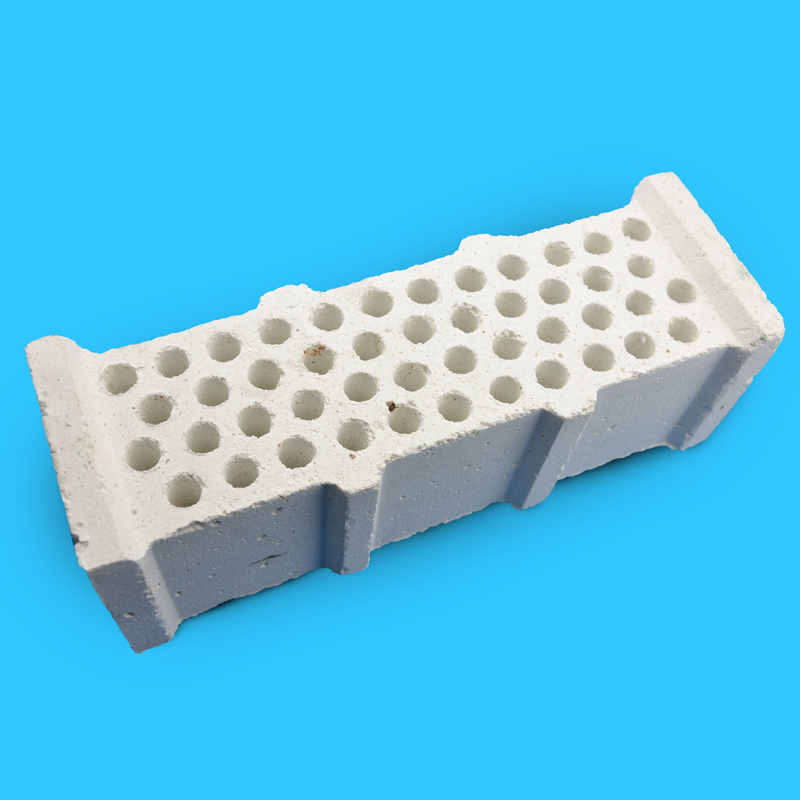

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Factory made hot-sale Hollow Floating Ball Vendor - 17% Inert Ceramic Ball – Catalyst Support Media – Kelley, The product will supply to all over the world, such as: Rome, Vietnam, European, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.