China Gold Supplier for Hollow Ball - 92% Inert Alumina Ball – Catalyst Support Media – Kelley

China Gold Supplier for Hollow Ball - 92% Inert Alumina Ball – Catalyst Support Media – Kelley Detail:

Application

92% AL2O3 inert alumina ball is widely used in petroleum, chemical, fertilizer, gas, environmental protection and other industries. It is used as a catalyst covering carrier material and tower packing in the reactor. It has high temperature resistance, high pressure, low water absorption, stable chemical performance, and Withstand the erosion of organic solvents such as acids and alkalis, and can withstand temperature changes during the production process. Its main function is to increase the distribution point of gas or liquid, support and protect the catalyst with low strength.

Chemical Composition

|

Al2O3+SiO2 |

Al2O3 |

Fe2O3 |

MgO |

K2O+Na2O+CaO |

Other |

|

> 94% |

92% |

<1% |

0.1% |

<1% |

<0.5% |

Leach able Fe2O3 is less than 0.1%

Physical Properties

|

Item |

Value |

|

Water absorption (%) |

<4 |

|

Bulk density (g/cm3) |

1.8-2.0 |

|

Specific gravity (g/cm3) |

3.6 |

|

Free volume (%) |

40 |

|

Operation temp.(max) (℃) |

1550 |

|

Moh’s hardness (scale) |

>9 |

|

Acid resistance (%) |

>99.6 |

|

Alkali resistance (%) |

>85 |

Crush Strength

|

Size |

Crush strength |

|

|

Kgf/particle |

KN/particle |

|

|

1/8”(3mm) |

>40 |

>0.4 |

|

1/4”(6mm) |

>80 |

>0.8 |

|

3/8”(10mm) |

>190 |

>1.90 |

|

1/2”(13mm) |

>580 |

>5.8 |

|

3/4”(19mm) |

>900 |

>9.0 |

|

1”(25mm) |

>1200 |

>12.0 |

|

1-1/2”(38mm) |

>1800 |

>18.0 |

|

2”(50mm) |

>2150 |

>21.5 |

Size and Tolerance (mm)

|

Size |

3/6/9 |

9/13 |

19/25/38 |

50 |

|

Tolerance |

±1.0 |

±1.5 |

±2 |

±2.5 |

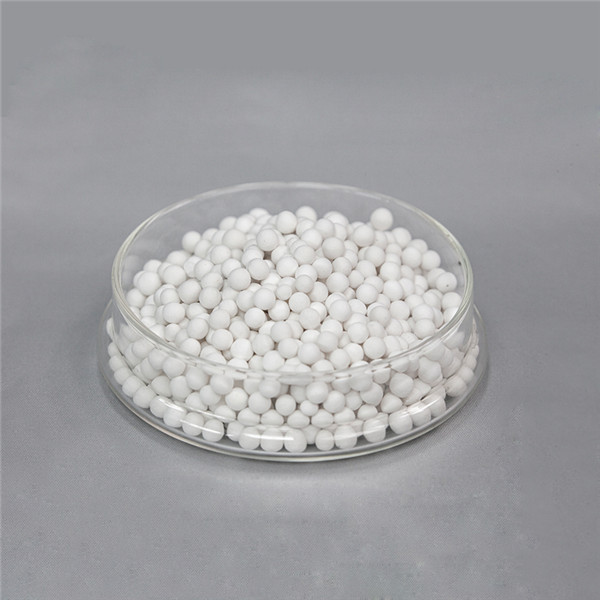

Product detail pictures:

Related Product Guide:

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for China Gold Supplier for Hollow Ball - 92% Inert Alumina Ball – Catalyst Support Media – Kelley, The product will supply to all over the world, such as: Algeria, Israel, Bahamas, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We provide wholesale prices on all our quality parts so you are guaranteed greater savings.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.