2021 New Style Plasticvsp Ring Column Packing - Plastic Raschig Ring with PP/PE/CPVC – Kelley

2021 New Style Plasticvsp Ring Column Packing - Plastic Raschig Ring with PP/PE/CPVC – Kelley Detail:

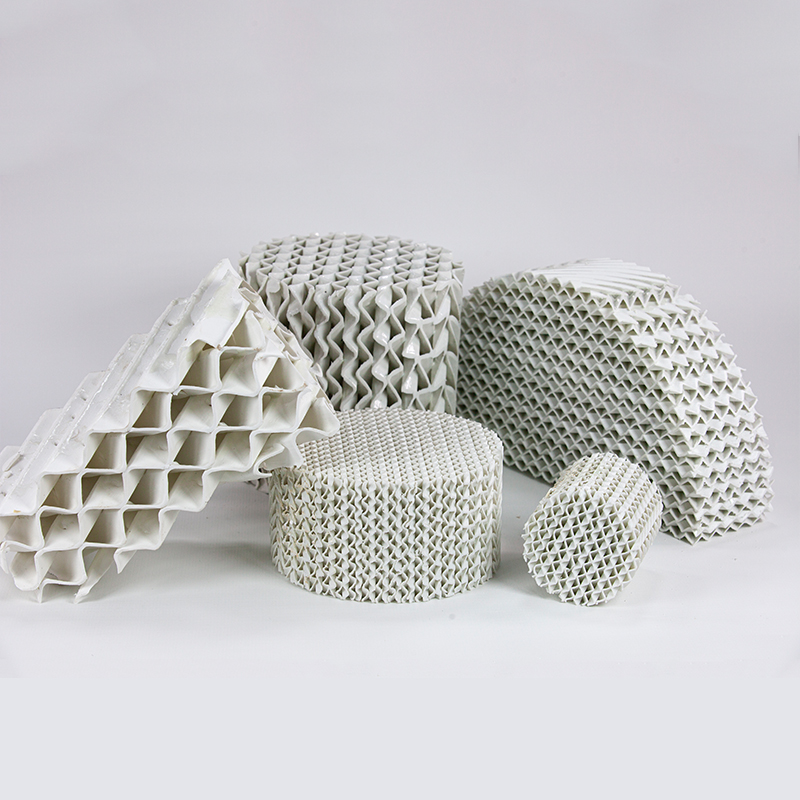

The invention of the Raschig Ring gave the packed column consistency and dependability. Raschig Rings significantly improved the operating characteristics of the column, enabling the performance of the packed column to be duplicated in a second column of equal size.

Because of their low cost, Raschig Rings remain one of the most widely used tower packing materials.

Technical Data Sheet

|

Product Name |

Plastic Rachig Ring |

||||

|

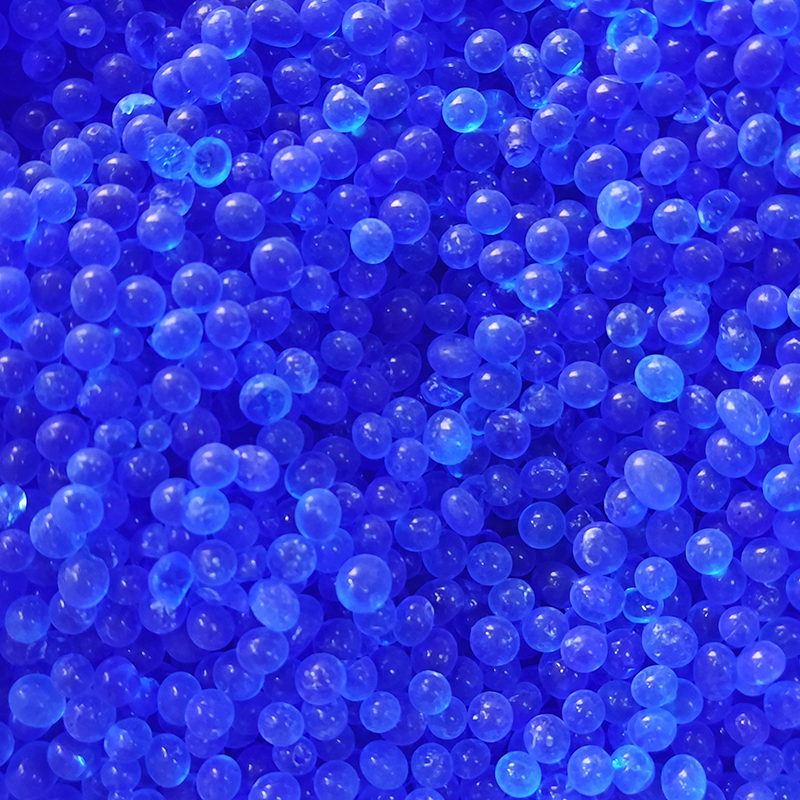

Material |

PP, PVC, CPVC, PVDF, PTFE, PE. |

||||

|

Life Span |

>3 years |

||||

|

Size mm |

Surface Area m2/m3 |

Void Volume % |

Packing Number pieces/ m3 |

Packing Density Kg/m3 |

Dry Packing Factor m-1 |

|

16 |

260 |

91 |

171000 |

94 |

490 |

|

25 |

205 |

90 |

50000 |

112 |

400 |

|

38 |

130 |

89 |

19000 |

70 |

305 |

|

50 |

93 |

90 |

6500 |

68 |

177 |

|

80 |

90 |

95 |

1820 |

66 |

130 |

|

Feature |

High void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high efficiency of mass transfer. | ||||

|

Advantage |

1. Their special structure make it has big flux, low pressure drop, good anti-impaction capability.2. Strong resistance to chemical corrosion, large void space. energy saving, low operation cost and easy to be load and unload. | ||||

|

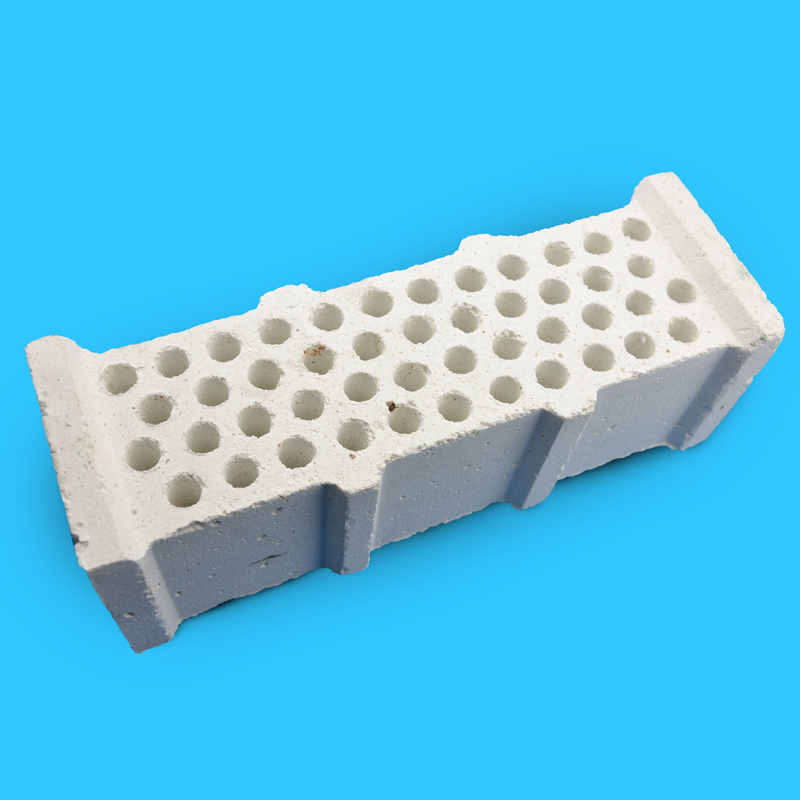

Application |

These various plastic tower packing are widely used in petroleum and chemical,alkali chloride,gas and environmental protection industries with max. temperature of 280°. | ||||

Physical & Chemical properties

| Performace/Material |

PE |

PP |

RPP |

PVC |

CPVC |

PVDF |

| Density(g/cm3) (after injection molding) |

0.98 |

0.96 |

1.2 |

1.7 |

1.8 |

1.8 |

| Operation Temp.(℃) |

90 |

>100 |

>120 |

>60 |

>90 |

>150 |

| Chemical Corrosion resistance |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

GOOD |

| Compression Strength(Mpa) |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

>6.0 |

Product detail pictures:

Related Product Guide:

We persistently execute our spirit of ''Innovation bringing growth, Highly-quality making sure subsistence, Administration marketing reward, Credit history attracting clients for 2021 New Style Plasticvsp Ring Column Packing - Plastic Raschig Ring with PP/PE/CPVC – Kelley, The product will supply to all over the world, such as: Oslo, Indonesia, Burundi, We will continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.