2022-07-29

1. The separation efficiency of structured packing is high, and the extraction rate of the rectification tower is high. The oxygen and nitrogen extraction rates of the air separation equipment are divided into two types: the extraction rate of the complete set of equipment and the extraction rate of the rectification tower. Due to the extraction rate of the complete set of equipment and the capacity of the air separation equipment . The output of liquid products is related to other factors. It is difficult to measure the high separation efficiency of structured packing. The extraction rate of the rectification column and the extraction rate of argon can better represent the design level of the air separation plant. sub-equipment. The oxygen extraction rate of its rectification tower has reached more than 99%; the argon extraction rate has reached 79%.

The operating value of the oxygen content in the sewage nitrogen in the upper tower is the main indicator of the extraction rate of the rectification and extraction. The actual measurement shows that the oxygen content in the sewage nitrogen can be less than 0.1%, and even reach 150-200x10-4%.

The upper column of structured packing and the crude argon column have high separation efficiency, which is the result of their greatly reduced operating pressure. The lower the operating pressure, the more favorable the separation of oxygen, nitrogen and argon, and the separation of oxygen and argon. . In general, the extraction rate of oxygen can be increased by 1% to 3%; the extraction rate of argon can be increased by 5% to 10%.

The extraction rate of the rectifying tower also depends to a large extent on the amount of expanded air entering the upper tower, which has a great influence on the extraction rate of argon. Therefore, the isentropic efficiency of the turboexpander and the booster ratio of the booster are continuously increased. , is the key to increase the extraction rate of the distillation column.

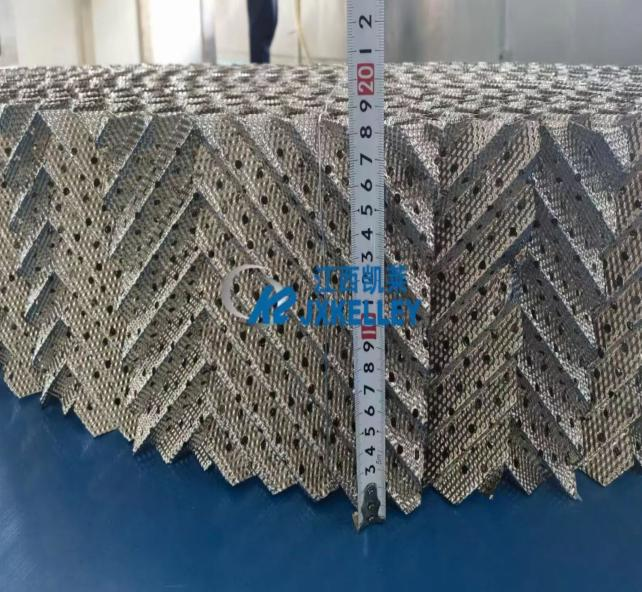

2. The void of structured packing is large, the production capacity is large, and the diameter of the tower is reduced to facilitate transportation

The porosity of structured packing can reach more than 95%. In the sieve plate column, the area of the orifice plate accounts for about 80% of the cross section of the column, and the opening rate is about 8 to 12%, which is far less than the air drop rate of the packing layer. For the same load, the column diameter ratio of the packed column The sieve tray tower is small; in general, its cross-sectional area is only ~70% of the sieve tray tower, which is beneficial to transportation for large-scale air separation plants.

3. The structured packing has less liquid holding capacity, larger operating fluid-to-gas ratio and elasticity, and fast changing working conditions.

The operating load of sieve tray towers is limited by sieve leakage and liquid flooding speed, while packed towers are only limited by liquid flooding speed, so their operating loads can vary within a wide range, and the design load range of packed towers can reach 40% ~120%, the oxygen output of the upper tower of the structured packing of the 12000m3/h air separation plant of Shanghai Iron and Steel No. 5 Plant can be adjusted within the range of 9000~14000mm3/h, and the operating load range is only 75%~117%.

Due to the small liquid holdup of the packed tower, it is generally only 1% to 6% of the tower volume, while the liquid holdup of the sieve tray tower is 8% to N% of the tower volume. The residence time is short and the operating pressure drop is small, which is also conducive to the operation of variable working conditions, but it should be verified in the actual operation of variable working conditions in the future.

4. The startup time of the device is greatly shortened

The start-up process of the air separation plant is no product output operation, so shortening the start-up time is one of the ways for the air separation plant to save energy and reduce losses. After using the existing structured packing, the amount of liquid it holds during normal rectification is greatly reduced, which greatly shortens the start-up time of the air separation plant.

Post time: Aug-01-2022