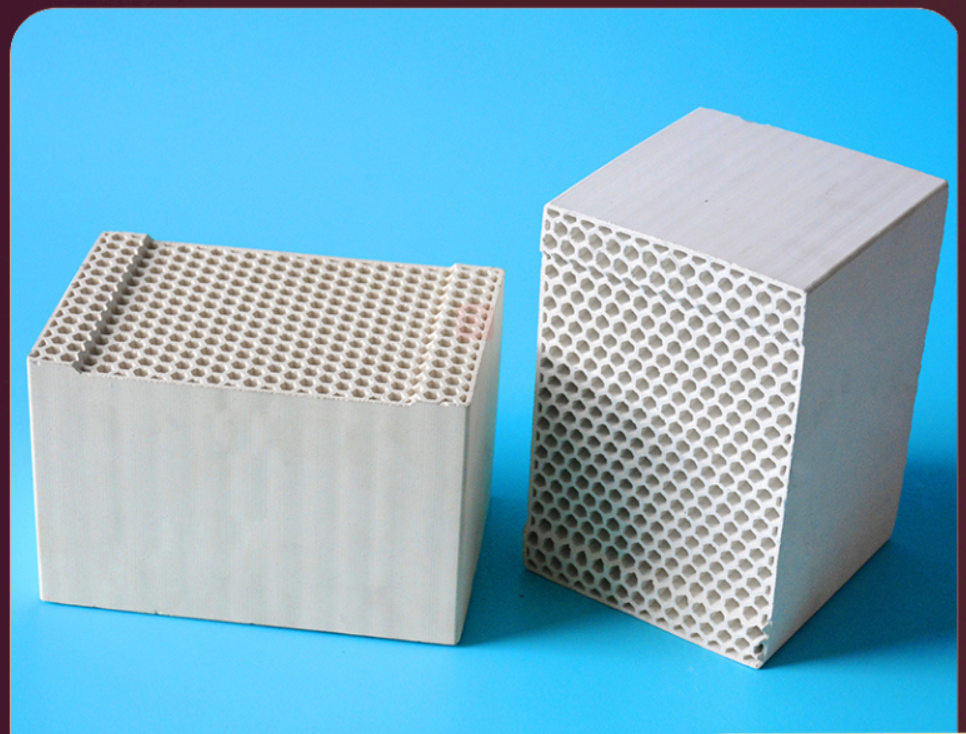

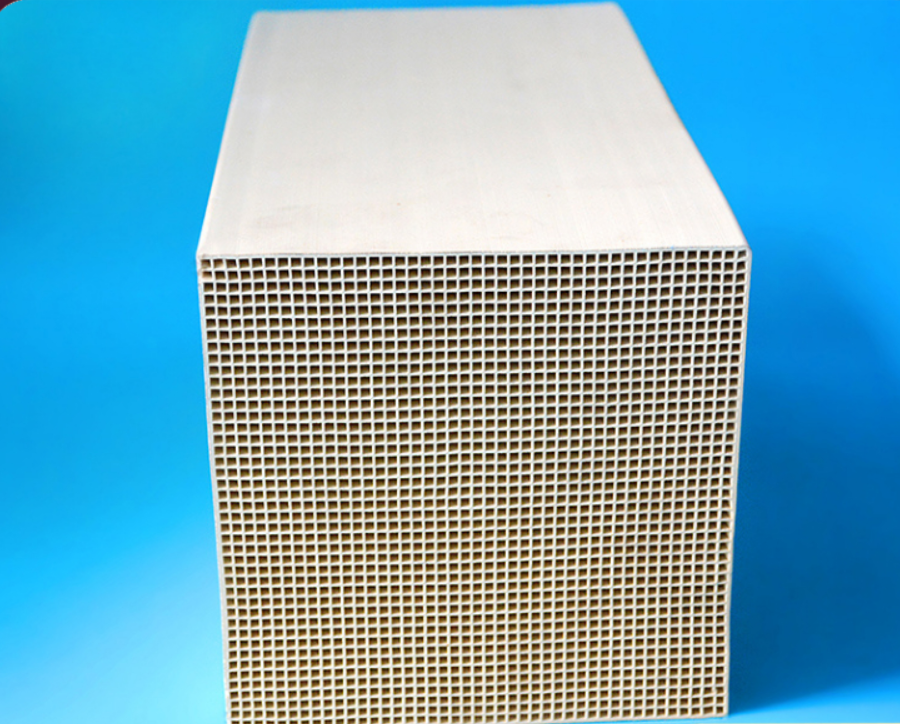

The use of honeycomb ceramic regenerator

The honeycomb ceramic regenerator has significant advantages such as high temperature resistance, corrosion resistance, good thermal shock stability, high strength, large heat storage, and good thermal conductivity, and the energy saving effect and service life are greatly increased. Honeycomb ceramic regenerator is the key component of regenerative burner, which is widely used in various heating furnaces, hot blast furnaces, heat treatment furnaces, cracking furnaces, roasters, In furnaces such as melting furnaces, soaking furnaces, and oil and gas boilers.

Problems existing in the use of honeycomb ceramic accumulators

The damage of the honeycomb ceramic regenerator in the regenerator is usually manifested on the high temperature side. The main reasons for the damage are as follows:

⑴High temperature reburning line changes greatly

If the reburning line of the regenerator changes too much, and abnormally high temperature occurs in the regenerator, the front row regenerator will form a large gap after shrinking due to the high temperature, which is easy to break the regenerator and form an excessively large gap. Clearance. When the flue gas flows through the heat storage box, it may bypass the heat storage body, so that the rear heat storage body contacts the high-temperature flue gas. If the temperature is too high, the heat storage box loses its heat storage function.

(2) Low softening temperature under load

If the softening temperature under load is too low, under the high temperature of normal use or when abnormally high temperature occurs, the front row heat storage body will collapse and deform, and there will be a large gap in the upper part of the heat storage tank.

⑶ Corrosion resistance can not be bad

The newly developed material should be a material with higher purity, which has better corrosion resistance to iron oxide powder and dust in the flue gas, reduces adhesion, and reduces the refractory performance of the regenerator caused by the reaction. damaged.

⑷ Poor thermal shock stability

During the use of the regenerator, the high-temperature flue gas and cold air should alternately pass through. For a certain point in the regenerator, its temperature should rapidly increase and decrease by 100-200°C periodically. This thermal shock affects the heat storage. Body material is destructive. For a certain time, there is a large temperature difference in the heat storage box. For a single heat storage body, the temperature difference of each part will form thermal stress inside the material. If the thermal shock stability of the material is not good, cracks or even breakage will occur due to these thermal shock and thermal stress surfaces shortly after being put into service. Generally speaking, cracks do not have a significant impact on use, but if the damage is serious, the flow channel will be blocked or a cavity will be formed in the regenerator after being blown out of the regenerator, so that the regenerator cannot function normally.

Honeycomb ceramic standard

1. Detect water absorption, bulk density, thermal expansion coefficient, softening temperature.

2. Detect the static pressure strength, thermal shock resistance, appearance quality and dimensional deviation of honeycomb ceramics.

3. Test method for detecting acid and alkali corrosion resistance of porous ceramics

4. Test method for detecting apparent porosity and capacity of porous ceramics

5. Detection of porous ceramic permeability

Post time: Apr-28-2022