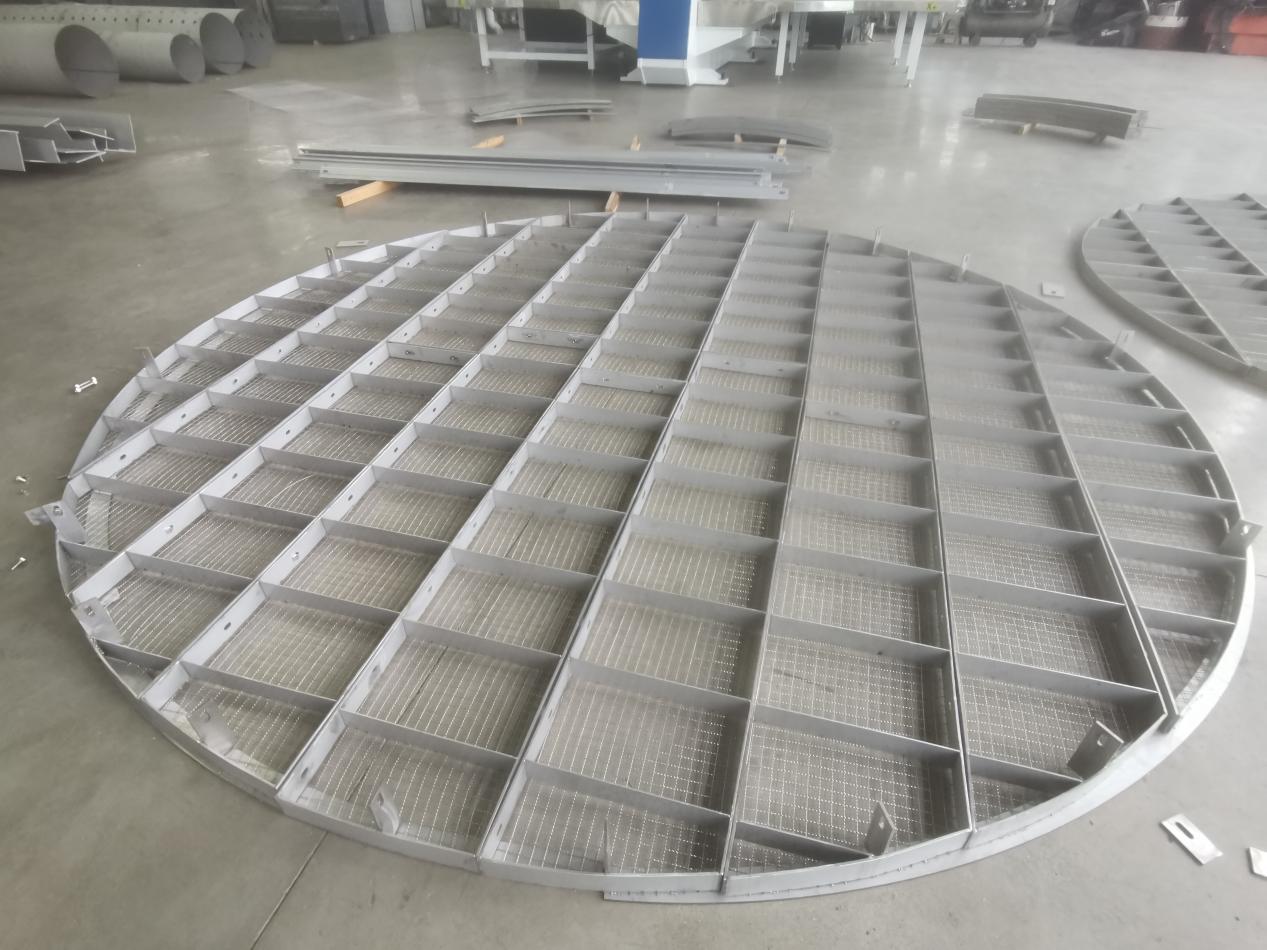

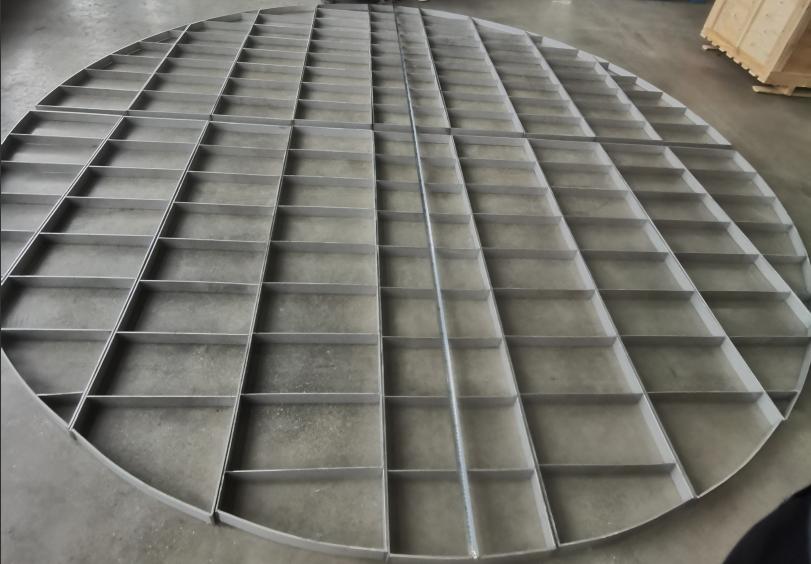

Recently Our valued customer has placed many orders for duplex 2205 baffle plate demister with different size, normally one whole set includes support grid and bed limiter.

The product is used for flue gas desulfurization, so it is also called: desulfurization demister. The baffle plate demister features a simple structure, high capture efficiency for medium and large-sized droplets, relatively low pressure drop and easy flushing. It also has an open structure for convenient maintenance and low cost.

The working principle of the baffle demister is mainly based on the following aspects:

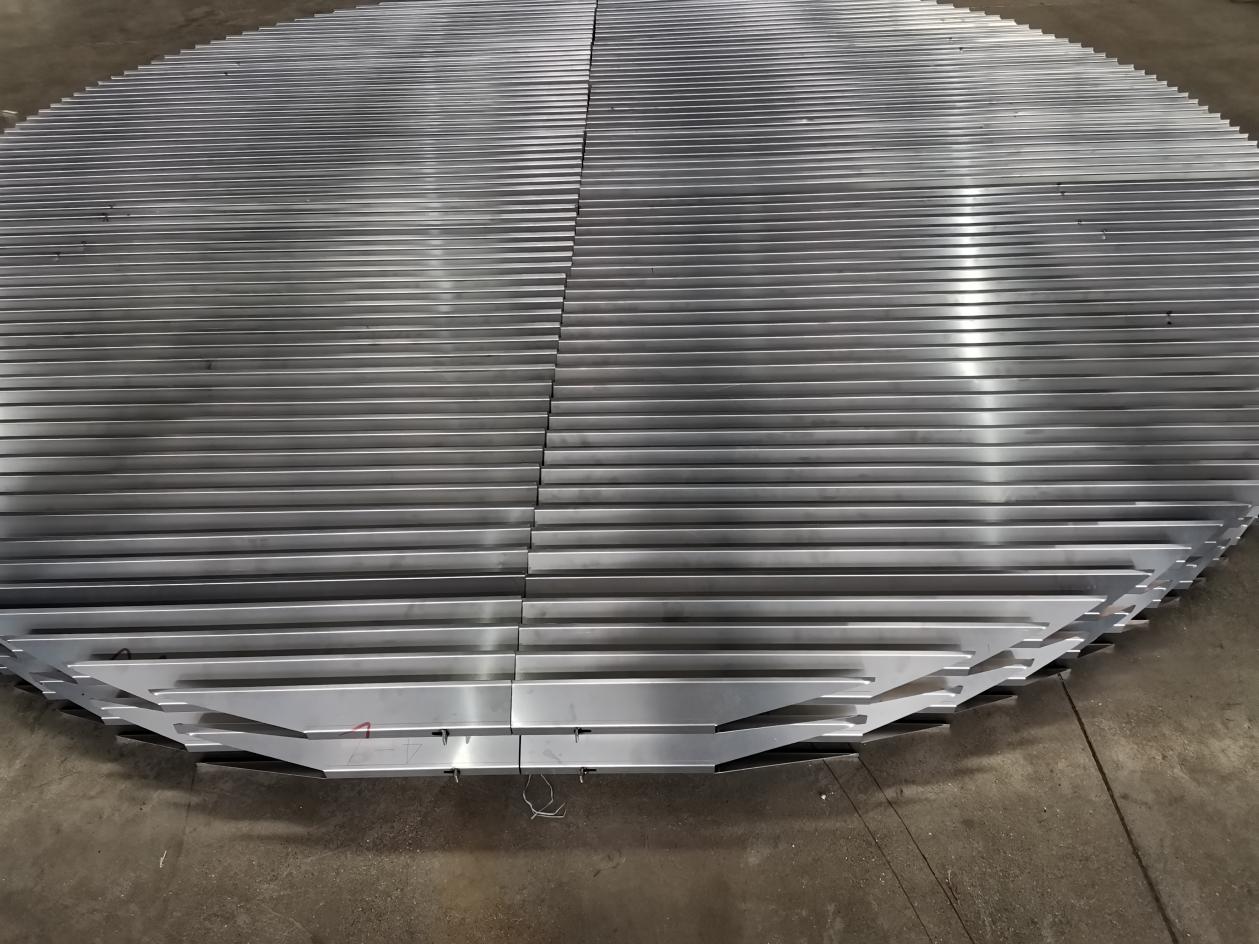

- Inertial separation: When the gas containing droplets enters the baffle demister, the gas flow path will change many times due to the obstruction of the baffle. Since the droplets have inertia, they will continue to move in the original direction, thus colliding with the baffle, so that the droplets are separated from the gas and attached to the baffle.

Gravity sedimentation: The droplets in the gas tend to settle downward under the action of gravity. The structural design of the baffle demister reduces the speed of the gas during the flow process, creating conditions for the gravity sedimentation of the droplets. Larger droplets are more likely to settle on the baffle or directly fall to the bottom of the equipment under the action of gravity.

Coagulation: After the droplets in the gas collide with the baffle, a liquid film will form on the surface of the baffle. After the subsequent droplets come into contact with the liquid film, they will be adsorbed by the liquid film and condensed into larger droplets. When the droplets are large enough, they flow downward along the baffle under the action of gravity, thereby achieving gas-liquid separation.

Key structural design

Material selection: Usually stainless steel, aluminum alloy or fiberglass and other anti-corrosion materials are used to adapt to high temperature and corrosive environments.

Flow rate control: The optimal flow rate range is 3.5-5.5 m/s. Too low flow rate will reduce the inertial separation effect, and too high flow rate may cause secondary entrainment.

Installation method: Horizontal installation saves space but is prone to secondary entrainment; vertical installation has a more stable separation effect.

Typical application scenarios

Mainly used to remove sulfate-containing droplets (10-60 microns) in wet flue gas desulfurization systems to prevent subsequent equipment corrosion. It is also widely used in gas purification in the chemical, power and other industries.

Post time: May-12-2025