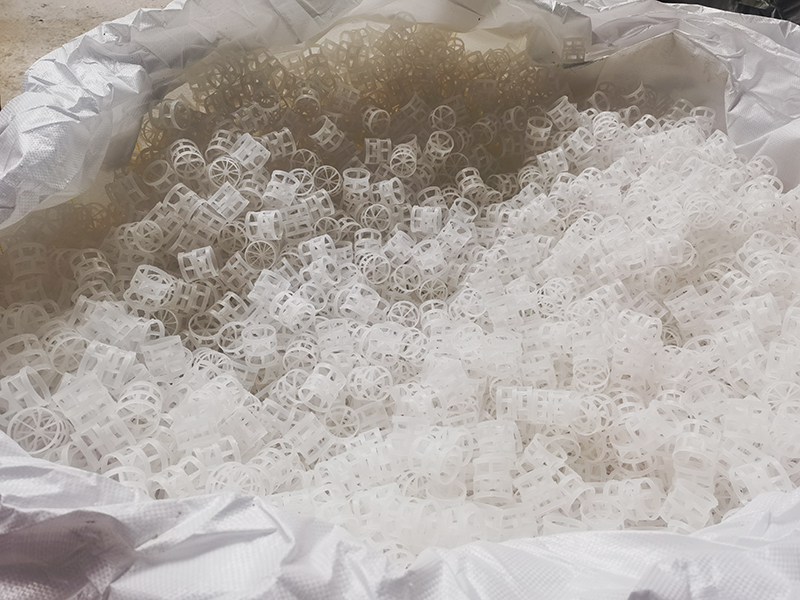

In the chlor-alkali industry, chlorine absorption towers and drying towers are core equipment, and their operating efficiency directly affects product quality and production safety. CPVC (polyvinyl chloride) Pall ring packing, with its excellent corrosion resistance and efficient mass transfer characteristics, has become a key component in these devices, providing a solid guarantee for the stable operation of chlor-alkali chemical processes.

Material advantages: A perfect combination of corrosion resistance and high temperature resistance

CPVC (chlorinated polyvinyl chloride) is a high-performance engineering plastic produced by chlorinating and modifying PVC. Its chlorine content is as high as 63%-69%, significantly improving the material’s resistance to chemical corrosion. In the chlor-alkali industry, highly corrosive media such as chlorine, sodium hypochlorite, and sodium hydroxide place stringent requirements on equipment materials. CPVC Pall ring packings can withstand these media for extended periods, remaining stable even at 100℃, with a tensile strength of up to 50MPa. This effectively solves the problem of easy corrosion or oxidation of ceramic and conventional plastic packings.

Structural Innovation: A Leap in Performance for Pall Ring Packing

Pall ring packing is a significant improvement over traditional Raschig rings, with its core innovation lying in the multi-layered window design in the ring wall. These windows bend towards the ring center and overlap vertically, forming a unique open structure. This design allows gas and liquid to pass freely through the windows, significantly improving the uniformity of gas-liquid distribution and fully utilizing the inner surface of the packing. Experimental data shows that, under the same pressure drop, the throughput of Pall rings is more than 50% higher than that of Raschig rings; at the same throughput, the pressure drop is reduced by half, and the mass transfer efficiency is increased by about 20%. This characteristic of “high throughput, low resistance, and high efficiency” makes it an ideal packing choice in the chlor-alkali industry.

Application scenarios: Key equipment covering the entire chlor-alkali process

- Chlorine drying tower: Achieves deep drying of chlorine through efficient mass transfer, ensuring product purity;

- Absorption tower: In the process of chlorine absorption, it enhances gas-liquid contact and improves absorption efficiency;

- Scrubbers and chlorination towers: Utilizing corrosion-resistant properties, they safely treat chlorine-containing exhaust gases;

- Environmental waste gas treatment: Efficient desulfurization and decarbonization are achieved in waste gas purification devices.

In addition, this packing material is also suitable for chemical applications such as ammonia synthesis, atmospheric and vacuum distillation, and ethylbenzene separation, demonstrating its strong versatility.

Technical parameters and customization services

CPVC Pall ring packing is available in various sizes (DN16-DN100), allowing for flexible selection based on tower diameter, throughput, and operating conditions. Its technical parameters are as follows:

Specific surface area: 72-239 m²/m³ (depending on specifications);

Porosity: 90%-96%;

Dry packing factor: 80-299 m⁻¹.

Manufacturers such as Kelley can provide a one-stop service from material selection (CPVC, PP, PVC, etc.) to shape customization (star-shaped, cross-shaped, grid-shaped), and provide a variety of packaging solutions such as woven bags, ton bags, and wooden boxes to meet the needs of different working conditions.

Conclusion

CPVC (polyvinyl chloride) Pall ring packing, with its core advantages of “corrosion resistance, high efficiency, and long service life,” has become key to improving quality and efficiency in the chlor-alkali industry. Its innovative structure and deep integration with materials science not only solve the pain points of traditional packings but also provide technical support for the green transformation of the chemical industry. Choosing CPVC Pall rings means choosing a stable, efficient, and sustainable future for chemical production.

Post time: Dec-16-2025